Jumpers (or jumper wires) are probably the simplest components we can find on a breadboard. They are small wires that are used to form a direct electrical connection between two points on the board. There are many types of jumpers, but we’ll focus on two varieties that are commonly used with breadboarding: solid and stranded.

Solid Wire

Solid wire often comes in breadboard kits, sometimes in a container with separate compartments organized by the size of the wires. From end to end, the wire is 1 solid piece of metal, surrounded by a layer of colored insulation. The thickness is typically around 22 gauge (smaller gauge = thicker wire), and these wires tend to be more “stiff” and hold the shape of their bends. You can also buy a spool of solid wire, and cut it to specific lengths, stripping the insulation off the ends.

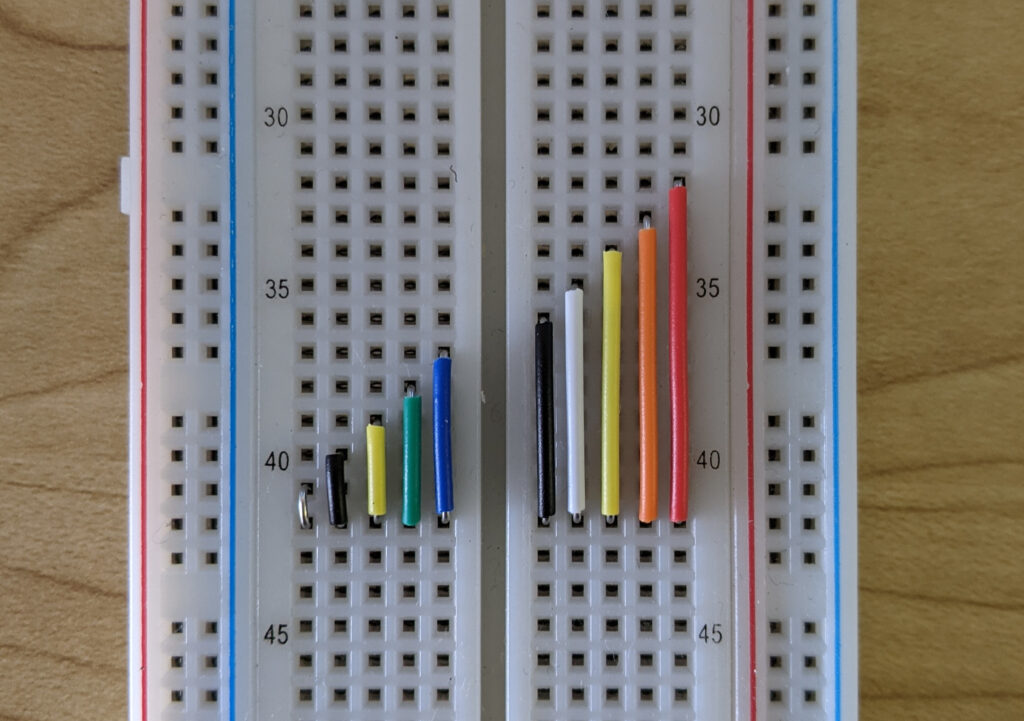

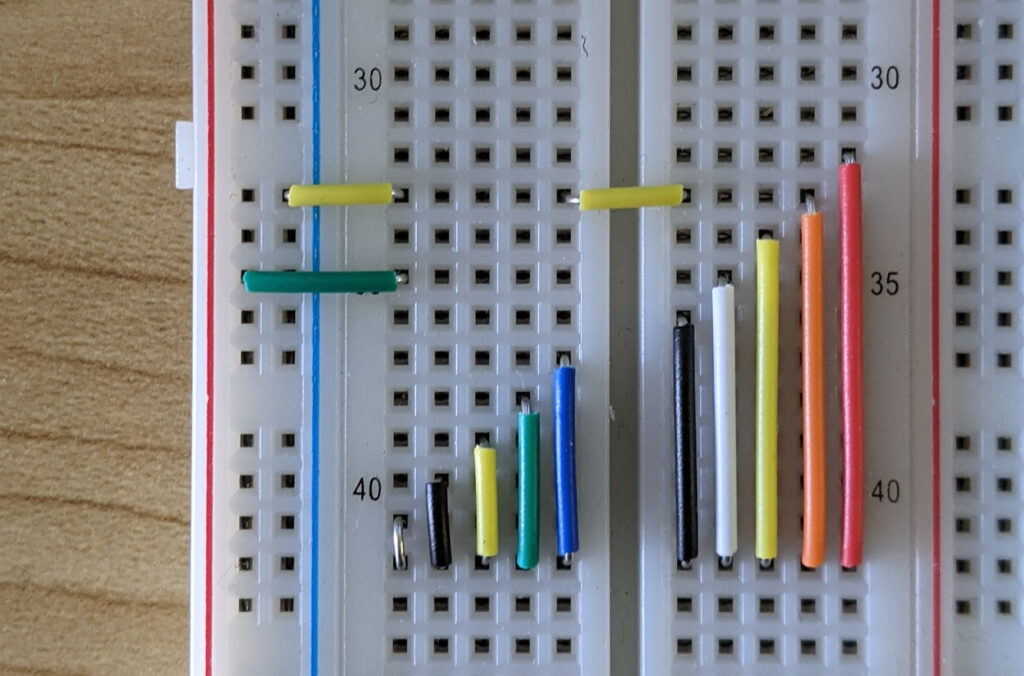

We’ll often find solid wire in pre-cut sizes, usually colored based on the size. The ends of the wires are usually bent at 90‑degree angles, forming the shape of a staple, and they are typically inserted flat against the breadboard.

The sizes are usually conveniently cut based on incremental distances between the points on the breadboard. This allows us to keep our circuit wiring neat and tidy, without the need to bend any wires.

The distance from one breadboard strip to another is usually equal to 3 points, so we can keep our circuit neat and flat, even when jumping the gaps.

Stranded Wire

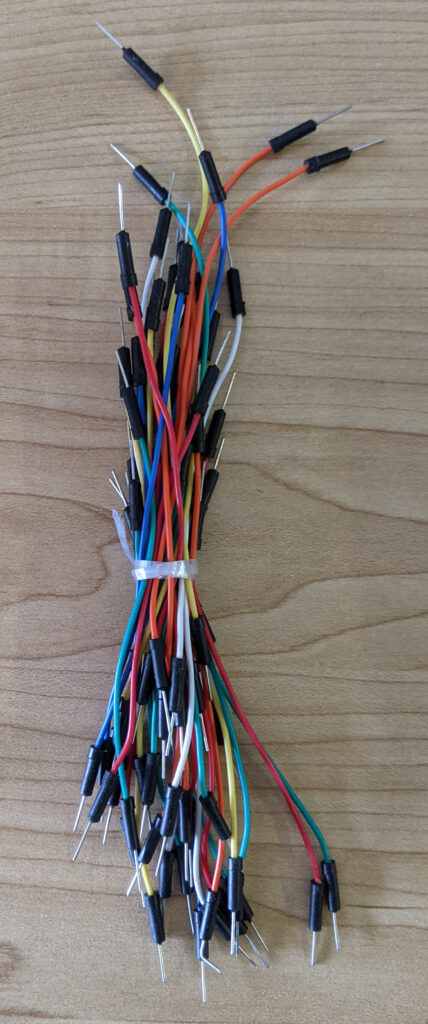

Stranded wire is also commonly used with breadboards, and sometimes comes in kits as either a strip or bundle. Internally, the wire is composed of several smaller wires, though they are usually terminated by a single pin at each end. It is usually found in a lighter gauge like 24 or 28, and is typically more flexible (with less “memory” of it’s shape) as a result of the internal construction.

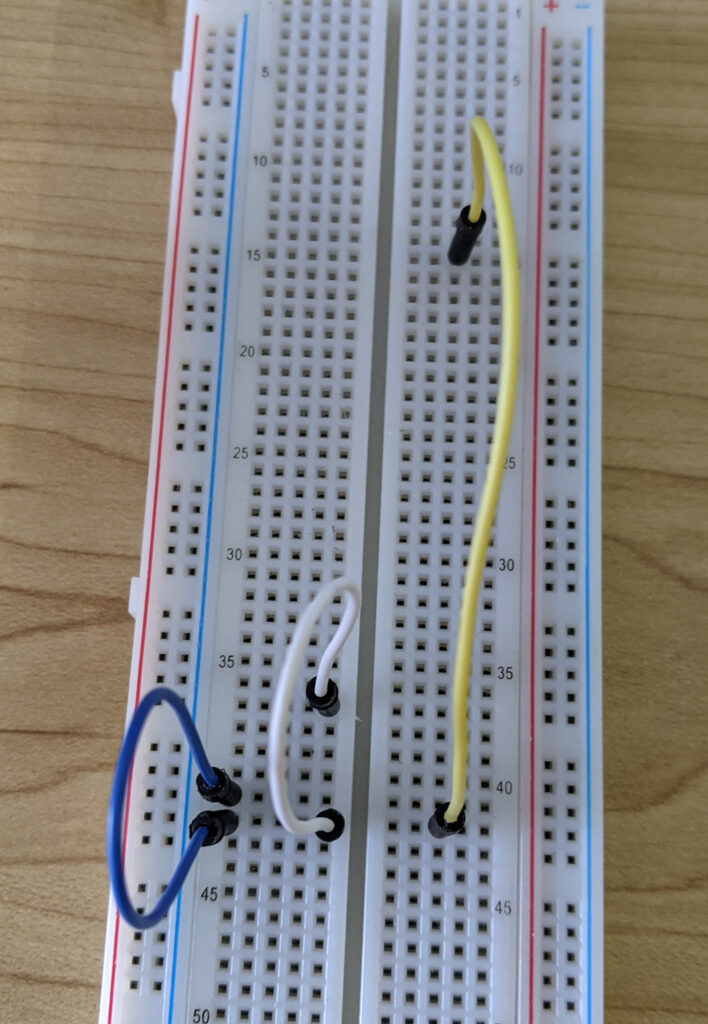

Flexible jumper wire often comes in varied colors, and sometimes different sizes too. The sizes are not necessarily related with the colors, nor do they align with specific distances between points on the breadboard. The ends of these wires tend to be straight, rather then bent at 90‑degree angles.

If a complex circuit is built using these wires, it can often look a bit “tangled”, since each wire usually has a lot of slack left over. However, these are a great option for spanning larger distances on the board without covering and blocking all the points in between, as a flatter wire might. Also, due to their flexiblity, these wires may be preferred for parts of a circuit where connections are changed frequently during experimentation.